Info Request

Ask A Question

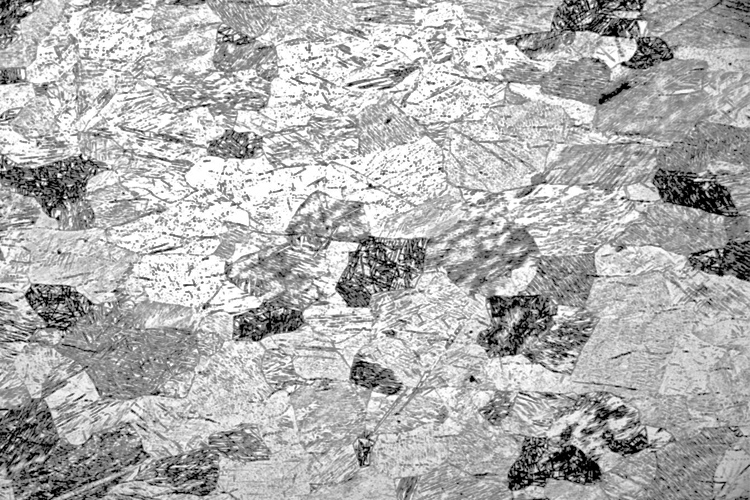

Our experienced technicians and metallurgists work closely with the analytical and

physical testing groups to provide an overall view of material characteristics so that

even the most difficult problems can be identified and solved quickly.

Conventional specimen preparation and automated polishing procedures using .03175m up to

.0508m diameter compression mounts ensure superior edge retention and flatness of

specimens. Other methods include cold mounting and slot polishing.

Light microscopes and metallographs using conventional and inverted stages are used to

characterize and photograph materials from 12X to 1200X for the following: